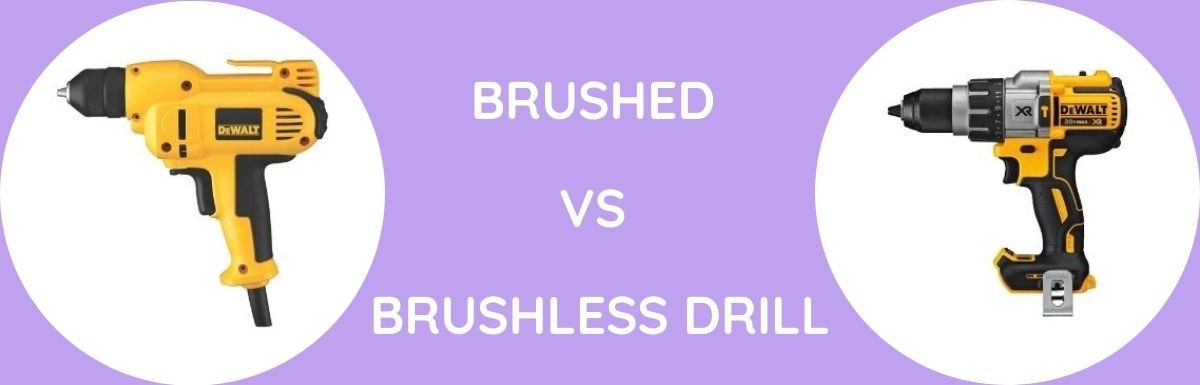

There is a big hype going around between a brushed and brushless motor drill, which one to use which one works better the limitations, and so on, A typical motor drill is designed to convert electric power to mechanical motion. In the market today, there are plenty of motors available, all of which handle different applications and require varying power. The two common types of drills that we will talk about are brushless and brush motors drills. There is significant confusion when it comes to these two tools, so we have researched these tools and written a detailed article hoping to help clear your confusion by providing a complete review on Brushed Vs Brushless Drill.

Contents

Our Verdict

It easy to pick the better tool since they are different in critical areas. We prefer the brushless motor drill as it is efficient, it does not heat much, and it lasts longer. Now, this tool is chosen for severe heavy-duty work, and it is expensive, so if it doesn’t fit your criteria or just a beginner doing light work, then a brush motor drill would work best for you.

Brushed vs Brushless Drill: Comparison Chart

| Specification | Single Miter Saw | Double Miter Saw |

|---|---|---|

| Affordability | Affordable | Expensive |

| Portable | Easy | difficult |

| Tilt | Single way | Both ways |

| Time-consuming | More | less |

| Speed and performance | Slow | fast |

Brush Drill Vs Brushless Drill: Differences

1. Battery Power

Since there are no brushes in a brushless drill, the energy that would be lost due to friction is saved; hence brushless motors are energy-efficient and have a battery life that is 50-percent more than brush motors.

2. Adaptable

A brushless motor is designed in a way to adapt the speed, torque, and power based on the task in hand, the power is used according to the material, whereas a brushed motor drill will use the same power irrespective of the task, or material its working with.

3. Maintain

A brushed drill requires more maintenance since the brushes have to be replaced, but this issue is not there with a brushless motor since there are no brushes.

4. Price

Brushless models are more expensive than brushed drills.

5. Long-Lasting

Brushless motor drill lasts longer than a brush motor drill.

6. Design

Brushed motor drill variants are made of carbon, and the brushless motor drill use magnets to generate power.

7. Carbon Brushes

a brushed drill uses carbon brushes, which need to have contact with the commutator, and the brushless motor drill does not have carbon brushes.

Brush Drill Vs Brushless Drill: Similarities

1. Weight

Both the tools weigh the same.

2. Spinning

In both brush motor drills and brushless drills, electric motors and magnets are responsible for their motion.

3. Operating Functions

Both brush and brushless drills have the same operating principle.

Brush Drill Vs Brushless Drill: Features

Features Of A Brushless Motor Drill

- The number one feature of a brushless drill is low maintenance; since this tool does not come with brushes, there is very little maintenance required.

- The brushless motor drill consumes Less power.

- Lightweight: this tool is lightweight, which makes it easy to carry around.

- Brushless motor drills are Adaptable.

- It does not get very heated: no friction means reduced heat, and since this tool is brushless, it does not get heated.

- Performance: the performance of a brushless motor drill is high.

- It is used to assemble motors.

- Long-lasting: since brushless drills are brushless, they have a 50-percent longer battery life as no energy is lost due to friction.

- Responsive and adjustable: a brushless motor drill can sense the power, torque, and speed required for a task; if you are working on a light material, this drill can sense that, and the power supplied will be limited if your task is a heavy-task then the power supplied which change according to that requirement.

Features Of A Brush Drill

- Power: the same amount of power is used no matter what task is done.

- Heated: because of the friction caused by the brushes, this tool gets heated.

- Brushes: brushes are the key design in this tool.

- Maintenance: since this tool has brushes, maintenance is required.

- The brushes in a brush drill are carbon brushes.

- Affordable tool: this tool is very affordable, so if you are a beginner or if you are on a budget, then you should get your hands on this tool.

- Simple to use.

- Easily repairable: although the brush motor drill requires maintenance, it is easy to maintain, the brushes can be easily repaired or replaced, you don’t need to go to a mechanic to get it done; you can do it yourself.

Brush Drill Vs Brushless Drill: Overview

Overview Of Brushless Motor Drill

Brushless motor drills are tools that use a magnet to generate power. This tool is becoming very popular among DIYers, homeworkers, contractors, and professionals. This tool has been around for more than 50 years, Since they do have brushes, they are less prone to wear and tear, and they are easy to maintain, thus being cost-effective,

This drill is designed to adapt its speed, power, and torque according to the work that it is used for. The circuit board allows the tool to sense how much power is required to complete a task. If the drill is working on lightwork like removing screws of drywall, the power produced is less based on the material, and if it is used for heavy tasks, then the power is more, the power of this tool varies according to the need of the task it is being worked on.

A brushless motor drill works by converting DC into a 3-phased variable frequency to generate a rotating field. Unlike the traditional drills, this drill only has magnets and an armature; this allows smooth and fast connections. The internal motor can generate up to 100,000rpm. Brushless motors are stronger than regular drills, which is why it is mostly preferred.

- Less maintenance

- High battery life

- Adjustable power supply

- Less noise

- Expensive

- A little complex to use

Overview Of Brushed Motor Drill

Brushed motor drills are composed of four parts: carbon brushes, magnets, armature, and commutator. All these parts work together to create the drilling motion. The electric current is sent from the battery to the brushes.

The brushes are the essential features of a brushed motor drill. The power supplies in a brushed motor drill are the same irrespective of the task it is being used for. This tool is cheaper than a brushless motor drill; they are reliable and have high torque. The direction of the electricity in this tool is reversed two times per cycle; this is done with the help of the rotating switch.

The unique feature of a brushed drill is the carbon brushes and commutator. The speed range is low due to its design. Since this tool has brushes, there is a high chance of wear and tear, but it is very to replace or repair. There is no need to go to a mechanic for this, it can be repaired at home, and you do not have to be a professional to repair this tool. The brushes are fixed light, which makes it easy to remove and replace.

- Affordable

- Reliable

- Simple to use

- Easy to repair

- Less battery life

- High maintenance

- Brushes wear off

- A high amount of heat and noise

FAQs

1. How does motor work?

A typical motor is made of few components. They convert electricity to mechanical rotations magnetic fields are fed. This causes the magnets to spin rapidly, which makes the shaft rotate, and this is how they work.

Conclusion

A brush motor drill is a traditional, simple to use a drill. It is inexpensive and can be used by beginners as well as professionals. This tool has a standard power supply, which means that irrespective of the task being done, the power used for light-task and the heavy-duty task will remain the same.

On the other hand, a brushless drill is expensive; it is getting popular among DIYers, professionals, and contractors; since this tool is brushless, there is no maintenance required. It has a longer lifespan.

The main feature of a brushless tool is its design to adjust power. This means that the power supplied depends on the task that it is used for. If a light-task is done, then the power is supplied according to the task needs, and vice versa, the noise produced is also less. Both these drills are great; based on your need, you can decide which one fits you best.

Leave a Reply