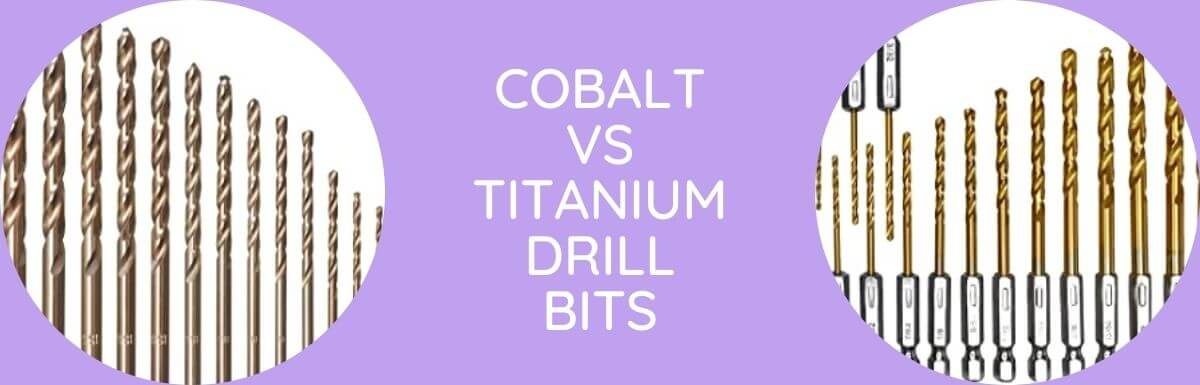

Cobalt and Titanium drill bits are the two favorite bits in the market. In most cases, you can do the same job with both of them. But if you use them wisely, you can use their features to do your work efficiently. Both of them are better than the other at specific tasks. It is essential to know their characteristics, uses, pros, and cons. In the following comparison, Cobalt Vs Titanium Drill Bits, you will learn about each type and when should you prefer which drill bit.

Contents

Our Verdict

Both the drill bits are made for slightly different purposes. Cobalt drill bits are mainly for more challenging materials. They are more durable and long-lasting. Titanium ones are for softer materials. They also are less expensive.

Cobalt Vs Titanium Drill Bits: Comparison Chart

| Specification | Cobalt Drill Bits | Titanium Drill Bits |

|---|---|---|

| Composition | High-speed steel + cobalt | High-speed steel with titanium coating |

| Colour | Golden | Golden, Blue-grey, Black |

| Compatible materials | Harder materials | Softer materials, plastic, wood |

| Temperature resistance | High | High |

| Durability | High | Comparatively low |

| Sharpening | Possible | Possible, but it is harmful |

| Cost | High | Low |

Cobalt Vs Titanium Drill Bits: Differences

1. Composition

The Cobalt drill bits are made of steel and cobalt alloys. They don’t have any coating. While the titanium drill bits are also made of steel, but they have a coating of titanium. This coating makes them hard.

2. Temperature Resistance

Both the drill bits are made of metal. Thus, a lot of heat is emitted while drilling. Although both drills have high resistance, cobalt has the edge here. It can withstand temperature up to 1100 degrees Fahrenheit. An added advantage of cobalt is that it distributes energy to the contact surface. Thus, it can work smoothly even at very high speeds. Titanium usually acts as a barrier between steel and metal surface. But its efficiency decreases as the coating loses its grip over time.

3. Sharpening The Bits

Over time, drill bits become dull when used frequently. The disadvantage with titanium bits is that the coating goes off with time. This happens when the coating rubs against the metal surface being drilled. Thus, they don’t remain in shape anymore. At the same time, cobaltcobalt has no such coating. Which means you can sharpen and use it again and again.

4. Compatible Materials

Both the drill bits can drill into most of the materials, including plastic, wood. Metal etc. But they both are better over others in some materials. Cobalt drill bits are better for hard materials like Cast iron and stainless steel. They are suitable for adhesive and abrasive metals. Titanium drill bits are usually preferred for softer materials, such as plastic, PVC, wood, soft metals, etc. In titanium drill bits, the coating also matters. Different coatings are suitable for other uses. Like TiCN is for more challenging materials, TiN is for relatively softer materials, etc.

5. Durability

Since Cobalt drill bits can be sharpened and used again, they are generally more durable than Titanium ones. You don’t need to replace them often.

6. Cost

Cobalt drill bits are more expensive than titanium drill bits. This means an expensive starting investment. But in the long term, it pays off as cobalt drill bits are much more durable and can be used repeatedly. Titanium drill bits are cheaper than Cobalt drill bits. But they have a shorter life span.

Cobalt Vs Titanium Drill Bits: Similarities

Cobalt and Titanium drill bits ( see the comparison) are mainly composed of high-quality steel. Both are heavy duty and have high efficiency and speed. Heat is dissipated in both of them. Both are compatible with hard and soft materials. However, there are some benefits of using one over others.

Cobalt Vs Titanium Drill Bits: Features

Features Of Cobalt drill

- High resistance to temperature

- Highly durable

- Versatile nature

- Compatible for hard materials

Features Of Titanium Drill Bit

- Made of high-quality steel

- Coated with titanium

- Compatible with softer materials

- Different coatings available for various uses

- More durable than regular bits

Cobalt Vs Titanium Drill Bits: What’s In The Box?

Cobalt Drill Bits

- Drill bits of various sizes

- core drill bit

- power tool accessories

- plastic case

Titanium Drill Bits

- Drill bits of different sizes

- Plastic case

Overview Of Cobalt Drill Bits

If you need long-lasting drill bits, cobaltcobalt is the best material. The cobalt drill bits are composed of cobalt and steel. They don’t have a titanium coating. A lot of combinations are available. M35 grade drill set has 5 percent cobalt. M42 grade bit has 8 percent cobalt. Each grade differs in usage. A Higher share of cobalt makes the drill more brittle. But it also increases the heat resistance of the drill bit.

Cobalt drill bits are generally more expensive at the start. But the value for money is very high when it comes to longevity. A cobalt bit of good quality lasts a very long time. Cobalt drills are easy to sharp. This means you can get the most of them by sharping. They are also tough and well made.

Thus they don’t become dull very quickly. Being gold in color, you can easily spot them in your toolbox among all the other tools. Cobalt bits have very high resistance towards heat. They can stand to temperature up to 1100 degrees Fahrenheit. This quality enables them to stay undamaged when rubbed against other metals. Not many drill bits can withstand high temperatures.

Being versatile, cobalt bits find use everywhere. They are suitable for industrial, commercial, and also for home use. You can use them on various metals. The list includes stainless steel and cast iron as well. They can also be used with abrasive metals. You can use the cobalt drill bits on soft materials also. But with some caution. While using cobalt bits on wood, you might damage the wood and split it. This happens as cobalt bits don’t have brad. Thus, when using it on softer materials, you should handle it with care.

- Higher resistance to temperature

- High efficiency

- Durability

- Versatility

- High cost

Best Cobalt Drill Bits In The Market

1. DeWalt DWA1240

- Connectable accessory storage system to optimize storage space of drill bits for wood, metal or i-beams

- Patented bit-bar design allows easy removal of drill bits and customizable placement

- DEWALT drill bit set comes with clear lid allowing you to easily see contents at glance

This set is designed to give maximum speed and life. They are made of steel and cobalt. A pilot point and a split-tip design give more control while working. It is suitable for stainless steel and other hard materials. The 14-piece set contains bits of various sizes.

2. Bosch CO14B Cobalt M42 Set

- Cobalt M42 drill bit – provides upgraded M42 Cobalt jobber-length bits designed for durability, high heat resistance...

- Enhanced M42 alloy material – contains 8% Cobalt alloy that delivers 10x life vs. Standard bits

- High-heat resistant bits – withstand high-temperature applications for extended periods of time

These M42 drill bits have M42 alloy, which has 8 percent cobalt. They have 10x life than regular bits and can withstand high temperatures. The thick web-helix design gives more stability and enables faster removal of material. Split points, three-flat shank are additional features that make the performance better.

Overview Of Titanium Drill Bits

Contrary to its name, the titanium drill bits aren’t made of titanium. They have a core of steel. And have a coating of titanium. The titanium in the coating varies. They are available in lots of varieties. Titanium Nitride(TiN) is a preferable choice. It is durable, tough, and can withstand high temperatures.

TiN coater bits have higher efficiency and can be pushed faster. The disadvantage is that you can’t use them on aluminum. The fact is that you can use them, but it is not safe for aluminum. The coating may harm the aluminum. The coating is golden in color with a thickness of 2-4micrometers. Titanium Carbonitride(TiCN) coating is a very tough coating. It is suitable for machines which encounter high stress. You can use them with materials that are adhesive and abrasive. The blue-grey colored coating gives a smooth finish. The thickness is around 2-4 micrometers.

Titanium Aluminium Nitride(TiAlN) is the most durable coating. It extends the life of the drill bits by up to 10 times. Thus, it is preferred for regular use. It is an excellent upgrade from the other two types. It is also resistant to oxidation. You also have a higher cutting speed and, thus, a faster process. 1-4micrometers is the coating thickness. Titanium drill bits can resist temperature up to 1500 degrees Fahrenheit. The coating acts as a barrier. These drill bits are very tough and can drill quickly into hard materials. These drill bits are heavy-duty, efficient, and durable than other bits. When it comes to materials, they can work well with knotted woods as well.

Knotted woods are more challenging types that cant is worked upon by normal drill bits. You can also use them on PVC, plastic, steel, aluminum, brass, copper, and other materials. They are preferred in machines that cut metal and for drilling precise holes.

The prices of different titanium drill bits vary. But still, they are less costly than cobalt drill bits. A negative aspect is that you can’t sharpen and use the bits again. This means that once the drill becomes dull, you won’t be able to use it again. This is because sharpening leads to loss of coating. They also lose their heat resistance. Thus, you might have to but new titanium drill bits more often than a cobalt drill bit.

- Lower price

- Compatibility with Softer materials

- Expiration of coating

- No sharpening possible

- Not suitable for tough materials

Best Titanium Drill Bits In The Market

1. DeWalt DW1342 Drill Bits

- Speed Tip Reduces Walking

- Ideal for drilling in metal, wood, and plastics

- No spin shanks

These titanium drill bits are excellent for drilling into non-ferrous materials, wood, & plastics. They are ideal for both commercial and home uses. It has a speed tip design, which reduces the walking on start. The no-spin helps in keeping a bit secure. The bits come with a tough plastic case.

2. Mastercraft Titanium Twist Drill Bits

- HSS TITANIUM COATING: Classic HSS construction with titanium coating gives our bits a very high surface hardness and...

- 135 DEGREE SPLIT POINT: The N-shaped speed helix split point starts fast and reduces drill walking. Also clears dust,...

- INCLUDES HEAVY-DUTY CASE: Our heavy-duty case holds all 230 bits neatly for easy storage. The bit size index is printed...

Suitable for woods, plastics, and metals, these bits reduce friction and heat. Their lifespan is 6x of the moral lifespan. They feature 135-degree split points. The design minimizes walking and begins drilling very fast.

FAQs

1. Can I use cobalt drill bits for wood?

Yes, you can. But you have to be cautious as the cobalt drill bit might split the wood.

2. What is the color of Cobalt drill bits?

Cobalt drill bits are usually golden.

3. Can I sharpen titanium drill bits?

Yes, you can. But sharpening can harm the titanium coating.

Conclusion

The perfect choice depends on your choices and priorities. The choice may be budget-friendly bits, or heavy-duty bits, or the ones which last longer. Both the drill bits are better than all the other drill bits in the market. But their uses and properties vary. Cobalt drill bits are for drilling into more challenging materials. They are heavy-duty, heat resistant, and more durable but cost more. Titanium drill bits are for softer materials; they cost less and are also heat resistant but need replacement often. Thus, you need to look into the job needs and make the right choice. I hope this review was useful to you.

DeWalt DW1342 Drill Bits - Editor's Choice

Summary

These titanium drill bits are excellent for drilling into non-ferrous materials, wood, & plastics. They are ideal for both commercial and home uses. It has a speed tip design, which reduces the walking on start. The no-spin helps in keeping a bit secure. The bits come with a tough plastic case.

Leave a Reply