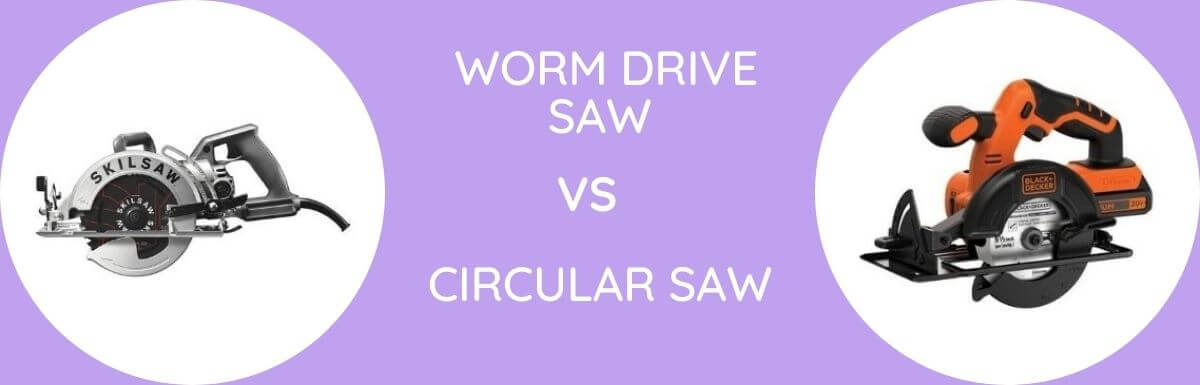

There are many reasons why it easy to get confused when choosing between either tool, which is why we have written this; in this article, you will read an in-depth study about both these tools, and hopefully, it will help you pick the one that you need. For clarification, a worm drive saw is a tool that is categorized under circular saws; they are like a type of circular saw. Still, they are very different in terms of features, specifications, and other aspects. In this article, we have compared Worm Drive Saw Vs Circular Saw.

Contents

Our Verdict

Choosing between either tool depends on the work in hand, the budget your willing to spend, and experience; a worm drive saw ( compare it with sidewinder saws) is expensive, powerful, and bulky; this tool can do difficult jobs with ease. Still one can get tired using this tool whereas a circular saw is lightweight easy to use has less power and is cheaper than a worm drive saw ( see the list). So for us, we prefer the worm drive saw since we need it for the kind of work that we are doing, and using a circular saw would be time taking (use track saw instead) .

Worm Drive Saw Vs Circular Saw: Comparison Chart

| Specification | Worm Drive Saw | Circular Saw |

|---|---|---|

| Power | More powerful | Less powerful |

| Price | Expensive | Budget-friendly |

| Weight | Heavy | Light-weight |

| Torque | Higher torque | Less torque |

| Form | Cord/cordless | Cord/cordless |

| Motor attached | At the rear | At the side |

| RMP | 4,500 | 6,000 |

Worm Drive Saw Vs Circular Saw: Differences

1. RMP

This stands for the rotation per minute, the RMP for a worm drive saw is 4,500, and the RMP for a circular saw is 6000; this shows that the circular saw has higher rotation per minute than the worm drive saw, they have a lower spinning rate.

2. Torque

When it comes to torque, the worm drive saw is seen to have more torque; this is because they are powerful are durable, which makes this tool handle high energy; the worm drive saw is designed to have large teeth this feature allows loading capacity which is much more than a circular saw.

3. Weight

Circular saws are lightweight and portable; this benefits the user to make uncommon cuts, a worm drive saw; on the other hand, is much heavier.

4. Blade Location

This is the significant difference between the two saws, the circular saws generally have blades on the right side, and worm drive saws have their blades on the left side.

5. Motor

The motor is located at the back of the saw in a worm drive saw, whereas, in a circular saw, the motor is located next to the blade.

The blade in a circular saw is located at the right side, which makes the weight of the tool on the left; because of this, it is difficult to see the cutline; on a worm driver, the blade is located on the left side, which means the weight of the tool is on the right side this makes following a cutline very easy.

6. Price

When it comes to price is one of the most important factors which determines this person will buy the tool; the worm driver saw it is more expensive than the circular saw, which is budget-friendly.

7. Maintenance

A worm drive saw needs oil to keep it lubricated although some saws come with the close system, all circular saws have closed systems, and therefore, they don’t need any lubrication.

Power speed and torque: there is an inverse relationship between speed and torque. This means that the faster the blade spins, the less torque it will have, and the slower the blade spins, the more torque you have; therefore, a worm drive saw has less torque and less speed, whereas a circular drill had less torque and more speed.

Worm Drive Saw Vs Circular Saw: Similarities

- These tools are available both in the corded and cordless form.

- They feature similar internal components like a battery/ motor and a blade.

- Both the saws can change the depth of cut and make bevel cuts.

- Blades on a worm drive saw and a circular saw is typically manufactured with carbide.

- Both the tools have blades ranging from 18- 80 teeth.

- Similar function: they both have motors that spin the blade to cut wood, plastic, and other materials.

Best Worm Drive Saws

1. Skilsaw SPT77WML-01 7-1/4 inch

- Lightest magnesium construction reduces user fatigue for less down time

- Cut-ready depth of cut system helps with quick, accurate depth measurements

- 53° bevel allows users to complete a wider variety of cuts

This is the lightest saw in this category; its power and torque allow it to go through difficult cuts; it has a dual field motor, which helps it stay cool when being used for long hours.

Features:

- This item weighs 11.5 pounds.

- The voltage is 20v.

- 15 amp.

- 5,300 RMP.

- This is a versatile saw.

- Has max cutting capacity of 2-3/8 inch at 90 degrees.

This tool is ideal to use for framing, decking, siding, and ceilings. It Works with soft, hard, and engineered woods.

2. DEWALT 7-1/4-Inch

- Power - Brushless motor of DEWALT 7 1/4 circular saw provides 5500RPM maintaining speed under load

- Runtime - The cordless circular saw provides 330 crosscuts in 2x4 (pine)

- Capacity - 7-1/4-inch blade of the compact circular saw provides 2-9/16-inch cutting capacity at 90 degrees

This tool is a lightweight, durable tool; it features a 53-degree bevel capacity.

Features:

- 15 teeth.

- This tool weighs 17.95 pounds.

- It has an electric brake.

- It has a durable magnesium footplate.

- 15 amp.

- 4,800 RMP.

3. Makita 5377MG Magnesium 7-1/4 inch

- Magnesium components create a lightweight saw (13.2 lbs.) that is well balanced and job site tough

- Oil bath technology is created with a built-in fan and sealed gear housing to ensure 100% oil surface coating for less...

- Large cutting capacity (2-3/8" at 90°) with positive stops at 22.5°, 45° and 51.5°

This is an electric-powered, powerful saw; it is a compact and durable saw.

Features:

- The speed is 4500 RMP.

- The voltage is 120v.

- This item weighs 13.2 pounds.

- It has a large cutting capacity of 2-3/8 inch at 90-degree and a bevel capacity 0-degree -51.5 degree with positive stops at 22.5 degrees and 45 degrees.

- High- quality.

Best Circular Saws

1. Makita SP6000J1 6-1/2 inch

- 12 AMP motor with variable speed control dial (2,000 - 5,200 RPM) for optimum performance in a variety of materials

- Large cutting capacity (2-3/16" at 90° and 1-9/16" at 45°). Power Type- Corded

- Bevel capability (-1 to 48°) with positive stops at 22.5° and 45°

This saw provides the user with a precision cutting system, which is splint free. It delivers straight and smooth cuts.

Features:

- It has a 12amp motor.

- 2000- 5200, RMP.

- It has a large cutting capacity of 2 3/16 inches at 90 degrees and 1 9/16 inches at 45 degrees.

- The Cord Length is 7.9 feet.

- This item weighs 8.71 pounds.

- The voltage is 110v.

2. Skilsaw SPT77WML-01

- Lightest magnesium construction reduces user fatigue for less down time

- Cut-ready depth of cut system helps with quick, accurate depth measurements

- 53° bevel allows users to complete a wider variety of cuts

This is a lightweight circular saw.

Features:

- This tool weighs 11.5 pounds.

- The voltage is 120v.

- It has 15amp of power.

- It features 53- degree bevel, which allows the user to complete a wider variety of cuts.

- It has a cut-ready system.

- 5,300 RMP.

3. DeWalt 7-1/4-Inch Circular Saw

- DEWALT 7 1/4 circular saw is one of the lightest saws in its class at 8.8 lbs

- Corded circular saw has 15 amp motor, powerful enough for even the toughest applications

- The compact circular saw has the bevel capacity of 53-degree with stops at 45 degree and 22.5 degree

This is a classic circular saw; it is light and powerful.

Features:

- It has a 15-amp motor.

- It has an electric brake.

- Comes with a dust blower.

- This tool weighs 8.8 pounds.

- The power source is electrically powered.

- It has 5,100 RMP.

How Does A Worm Drive Saw Work?

Worm drive saws are called so because they have a worm drive, the presence of a worm drive is what turns the blade of this tool, the blade is located at the front of the saw with the motor attached at the end, the power is transferred from the motor to the blade through a threaded worn drive shaft which turns both the gears set at 90-degree angle, and this makes the blade spin.

The blade is located on the left side of the saw.

The torque produced by the engine is high, but the Rotation Per Minute (RMP) is low about 4,500.

How Does A Circular Saw Work?

Circular saws have their motor located at the side of the blade so there is no use of gears; the motor directly turns the blade; this function is called direct-drive since its directly done without the involvement of any gears, most circular saws offer 6000 Rotations per minute.

These saws have a handle with a switch and an arbor nut; this keeps the blade in position. The blade is usually located on the right side.

Worm Drive Saw Vs Circular Saw: Overview

Overview Of Worm Drive Saw

Worm drives are the first portable circular saws ever to be invented; these saws are robust, heavy, and expensive tools; they are used for tough cutting jobs and is used on various materials; they RMP is at 4,500, this saw has high torque meaning great, clean and deep cutting power. The worm drives are another type of circular saws, where the blade is positioned at the front of the motor.

Vision is vital when working with tools, and this tool offers the user a clear view of the cutting line, making you see precisely what you are doing. A professional can use this tool with a single handhold. This tool is massive, which means beginners or semi-professionals might find it difficult and heavy to work with, thus making this tool, not their top choice. One significant advantage of this tool is that because of its bulkiness; the user can get tired when they use this tool.

- High torque

- Durable

- Cutting capacity

- Fast and reliable

- Cord and cordless

- Made for production

- Expensive

- Heavy

- Challenging to work with for long hours

Overview Of Circular Saw

Circular saws are versatile tools they can complete a lot of tasks; this tool is used by many professionals and hobbyists. Circular saws can make good angled cuts, bevel cuts, miter cuts. These tools are powerful with an RPM at around 6,000; they are lightweight and easy to use.

Ideally, circular saws are used for ripping, cutting, and cross-cutting hardwood, softwood, and other human-made wood. It is highly in demand because of its lightweight and portability.

- In-expensive

- Easy to use

- Light-weight

- Used for DIY projects by contractors and homeowners.

- Less torque

- Low cutting capacity

- Less speed

FAQs

1. When do I use either tool?

Since a worm drive saw has higher torque, this means it has the higher cutting capacity, so for tasks that need the extra power to get done, you should use a worm drive saw-like cutting through knotty wood, plunge cuts, etc.

2. As a beginner, can I invest in worm drive saws?

Yes, there are less advanced worm drive saws available today, which you can purchase; these are easy to use. Choose a saw that fits your needs and capabilities perfectly.

3. What are these tools used for?

Both these tools help to cut through wood, metal, plastic, and other materials.

4. Which tool weighs more a wood drive saw or a circular saw?

A wood drive saw weighs more than a circular saw, which is why it is not the most preferred tool when it comes to working for long hours as it tends to make the user more fatigue.

Conclusion

Both these tools are great, they get the job done, and there is no feeling of loss. For a heavy, challenging task, you need to use a worm drive saw, but for easy simple work a circular saw can be used,

So, consider all your factors like past experiences, the nature of your work, price before you buy the tool that works best for you!!

Skilsaw SPT77WML-01 7-1/4 inch - Editor's Choice

Summary

This is the lightest saw in this category; its power and torque allow it to go through difficult cuts; it has a dual field motor, which helps it stay cool when being used for long hours. This tool is ideal to use for framing, decking, siding, and ceilings. It Works with soft, hard, and engineered woods.

Leave a Reply